|

|

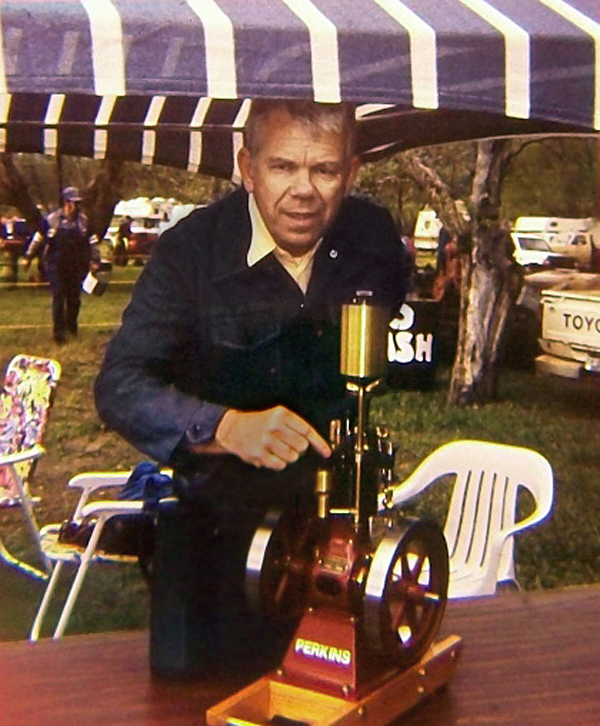

From the Internet Craftsmanship Museum:

Jerry Howell has been well known in the model

engineering hobby for a number of years. He attends the NAMES show and

a number of other shows almost every year with a beautiful display of

engines he has designed. The engines he has designed no doubt grace

many a desk or mantel of proud builders around the world. One look at

the finishes on his personal projects will tell you he is not satisfied

with any result less than perfection—they are truly beautiful. More

important to us at the Foundation, however, is the fact that he takes

the extra step beyond just making engines to that of designing and

producing plans and kits so that others can make them as well. Even his

plans go an extra step not usually found in engine kits, and that is to

show complicated parts at several stages of completion, making it

easier for a novice to take a raw block of metal to a finished engine

block. We were impressed enough with Jerry’s newest project to make the

Howell V-4 our next museum shop project. You can follow along as we

build it by going to the build

page.

|

A Model Builder from an Early Age

Jerry Howell was born and

raised in West-central Ohio. From a very early age he was interested in

mechanical things and especially things in miniature. It wasn't until

he was in his 50's that he found out where that trait probably came

from. His Dad told him of his grandfather who had built

a scale model of a house he was going to build. The model

included all the studs, rafters, etc. He then used the refined and

proven model as the plans to build his full size house.

Having had several electric train sets while

growing up created a fascination with steam locomotives. From

Jerry’s early teen years in the early 1950's he was always

into making box kites, wooden ship models, electric boats, balsa wood

gliders, rubber powered model airplanes, water pipe/firecracker

guns and soda straw/black powder rockets. Some of the soda

straw rockets had two or three stages and flew to several hundred feet

high. In metal shop class he turned a brass naval canon barrel which

developed into an interest in machining. He checked out every book

about steam engines, rockets/jets, astronomy and telescope

making from the library at least a half dozen times. His best school

subjects were physics and chemistry. Looking back, he says that he is

positive that all those things together had a large influence on what

he did later on.

After high school Jerry went to work for his father

driving one of his trucks picking up milk in 10 gallon cans

from farms 7 days a week. As a young adult he was into flying control

line model planes, and then later on, R/C planes and boats for

a while. Acquiring a 3" Unimat lathe in 1960 rekindled an

interest in machining and he used it to build fuel filters and

several throttles for his two-stroke engines in order to

improve idle reliability over the crude ones available at the time.

(Click image for larger view.)

Jerry built this radio-controlled model of PT-109 in 1968. It was built

from a Fibo Craft kit. The hull is fiberglass and the major deck

structures are wood. Deck details are white metal castings and the

torpedo tubes are aluminum tubing with red painted ping pong ball

noses. The boat is 39" long and weighs around 10 pounds. It is powered

by one of the first O.S. Wankel engines of the time. The engine is .29

cubic inch (about 5 cc) displacement and is fitted with a stainless

steel flywheel and a brass water jacket. A water pick-up is fitted

behind the propeller and after circulating through the engine jacket,

cooling water discharges into the exhaust pipe ahead of the muffler.

The tailpipe exits through the transom. A little whiff of white castor

oil smoke and steam vapor can be seen in each photo. There are two 8

ounce fuel tanks, one on each side of the prop shaft stuffing tube. A

fuel pump is belt driven from the prop shaft.

A Career Change Puts Machine Tools Back into

His Life

Jerry never cared much

for driving the truck, so when the opportunity came in 1962,

he took a job in Jacksonville, Florida as an apprentice making plastic

injection molds for a few years. Here he learned a lot about machining

and operating full size lathes, mills, other machines. During

that time he made his first engine—a little 1/4" bore oscillating steam

engine from bar stock at home on the kitchen table.

After a few years, he moved

back to Ohio and eventually bought and operated a construction

equipment business. Here his main hobby interest turned to HO model

trains for a couple of decades. His scratch built 0-6-0 switch

engine was an early Model Railroader magazine

Model-of-the-Month winner.

Getting into the Computer Business Adds

Computer Drawing Skills to His Repertoire

Selling the construction

equipment business and opening a computer store in the early 1980's,

Jerry learned about CAD software and has been using Drafix CAD

Ultra in designing his own projects ever since. He says he

would not have wanted to do most of

his projects without the use of CAD software.

In the mid 1980's he became

interested in "hot-air" engines, both the

atmospheric and the Stirling cycle. He

began building many types of these engines and as he went along found

that he enjoyed designing engines as much,

or more, than building and running them.

Requests from Friends Lead to a

Business Selling Kits and Plans

Beginning with the early NAMES

shows others were asking for plans to build Jerry’s

engines. He came by a used 1904 book showing wood

cuts of those beautiful late 1800's Victorian era large stationary

steam engines that really caught his

fancy. He started incorporating that Victorian style

into his engines, concentrating on esthetics. He began

designing his bar stock engines to look as much like

they were made from castings as possible and still not be too difficult

for the average builder to make. He notes that a pleasing model that is

to the eye only takes a little longer to build than a bare bones one,

and if it was worth doing at all, one should make it look as

nice as possible. Really well done models will become valued heirlooms

to be handed down long after the builder is gone.

There were a

few scale engines that Jerry wanted to make that just

couldn't be manually machined from solid stock and still look like they

were made from castings. Many of the parts were very small, so sand

casting was out. The answer was making lost wax castings. A jeweler

friend taught him the very involved process, and with the purchase of a

lot of high priced equipment, he made several detailed limited edition

castings kit engines in aluminum and also in zinc alloy. His favorite

of these is the "1 of 50" serial numbered Rider Compression

Hot-Air Pumping Engine which is now a collector’s item.

After designing so many of the

"hot-air" engines his interest turned to internal combustion engines.

Having acquired larger machine tools over the years, Jerry decided to

buy and build some antique model hit-n-miss IC and steam engine

castings kits. Over time, he has collected more than 25 of these kits

and has built some of them, with the rest being saved for "some

day". These kit engines inspired him to develop some

of his own bar stock IC engines. He saw there was a relative

lack of non-airplane type IC bar stock engines in the hobby, so he

turned his attention to that area. The first ones were single cylinder

and later came the air cooled 90-degree V-Twin and the liquid

cooled V-Four which features twin cams, Hall effect distributor,

pressure feed oil system, magnetic drive water pump and a water heated

intake manifold.

Jerry has always wanted his IC

engines to be doing something instead of running without a purpose.

Others have geared or belted their engines to can crushers, peanut

roasters, water pumps, etc., but having a fondness for stationary

industrial engines, he decided that a generator was about as

practical and clean a load that can be driven by a model engine. Also,

a permanent magnet generator (actually a DC motor) doubles as

a starter motor. All of the prototype internal combustion engines he

has designed since 1995 have the starter/generators as standard

equipment. They have sort of become his "trademark" engines at shows.

Over the years Jerry has attended more than 50 model engineering shows

and has met some of the finest folks on earth, and more than a few have

became close friends. Model engineering/machining is truly

one of the world's great hobbies!

Jerry’s project,

the "Howell V-Four" engine is currently the Foundation

Craftsmanship Museum Group Build project which he considers a

great honor.

Jerry visits with founder Joe

Martin and shop craftsman Tom Boyer on a visit to the Craftsmanship

Museum. (Vista, California / October, 2007.)

Jerry's Shop

Jerry owned an original 1960

Unimat DB200, although it had only been used with a buffing wheel for

polishing for the past 20 years. He also owned a Maximat 7 and Maximat

Super 11 lathe. In the mill department he used a Jet JVM-836 (manual

with Mitutoyo DRO and 6" Kurt Vise), and a Jet JVM-836 mill

that he converted to CNC with ball screws. The conversion was done in

January, 2007. His first CNC project was to mill the skids and the

exhaust rain caps for the Howell V-4 engine. He used either one of the

mills for drilling large holes, and his own Mini Drill Press for

everything under 1/4". There is also a cantankerous old Jet 5"

horizontal/vertical bandsaw that he always threatened to take

a sledge hammer to!

|

|

|

|

|

An Overall View of Jerry's 10 x 14' Shop

|

1968 Emco Maier Maximat 7 Small Gearhead Lathe

|

1990 Emco Maier Maximat Super 11 Lathe

|

Jerry's Personal Projects

(Click Images for larger view.)

Plans & Parts

| Ignition Systems | Bearings | Misc. Items | Boehm

Engine Kits

Contact Us | Catalog | Comments | Links | Forum | Model

Engineering Tips

| On the Road | Tribute

to Jerry

Copyright © 2010

Outpost Enterprises LTD. All Rights Reserved.

|